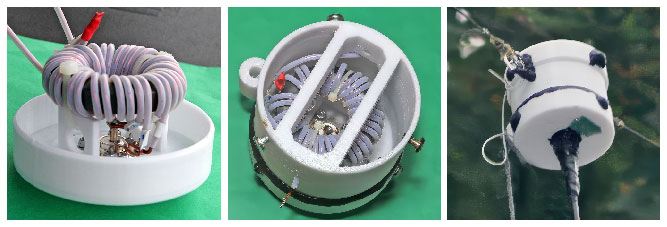

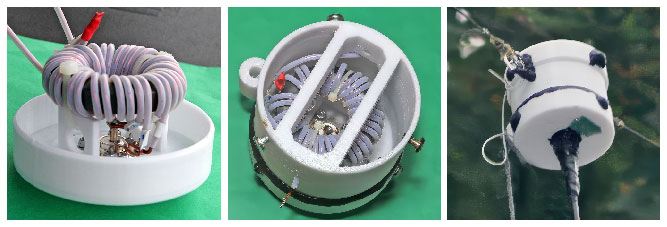

3D-printed Balun Case

After nine years, the Carolina Windom antenna begam acting erratically, so I replaced the original balun made from wire wound on a ferrite rod with one wound on a toroid core.

I didn't want the balun exposed to the elements, so I designed and 3D-printed a case to enclose it. I used PETG material to withstand the Sun and rain. These photos show the balun in the case, and hanging 40 feet above the ground.

From left-to-right:

-

The case bottom cap has an SO-239 connector, and "feet" to hold the balun above it. Cable ties through holes in the feet secure the balun.

-

The top view shows the balun and bottom cap installed. The case has thick bars across the top to take the strain from the antenna wire. The top cap (not shown) also adds strength.

-

The balun suspended in its normal position.

-

To the left of the coax cable is a 3/16" rope attached through the hole in the rounded tab visible in the center photo. The end of this rope is tied around the line isolator at the bottom of the 22-foot coax, to support it. This removes strain and prevents the cable from pulling loose from the PL-259 connectors.

-

The green rectangle is a piece of plastic pot scrubber glued over a drain hole to prevent mud daubers from plugging the hole.

-

All screws and eye bolts are stainless steel, and all cable connections and hole penetrations in the case are sealed with Coax-Seal.

Updated

April 18, 2025